Home ›› 11 Sep 2022 ›› Business Connect

In 1983, many small docks and boat-making factories in Bangladesh were only building small and medium-sized wooden boats to transport people and goods. It was around that time when a couple dreamt of locally building a big ship that will sail the oceans.

That year, naval architect Dr Abdullahel Bari and his wife Afruja Bari started Ananda Builders and set up their factory on the bank of Buriganga River with the aim to fulfil that dream.

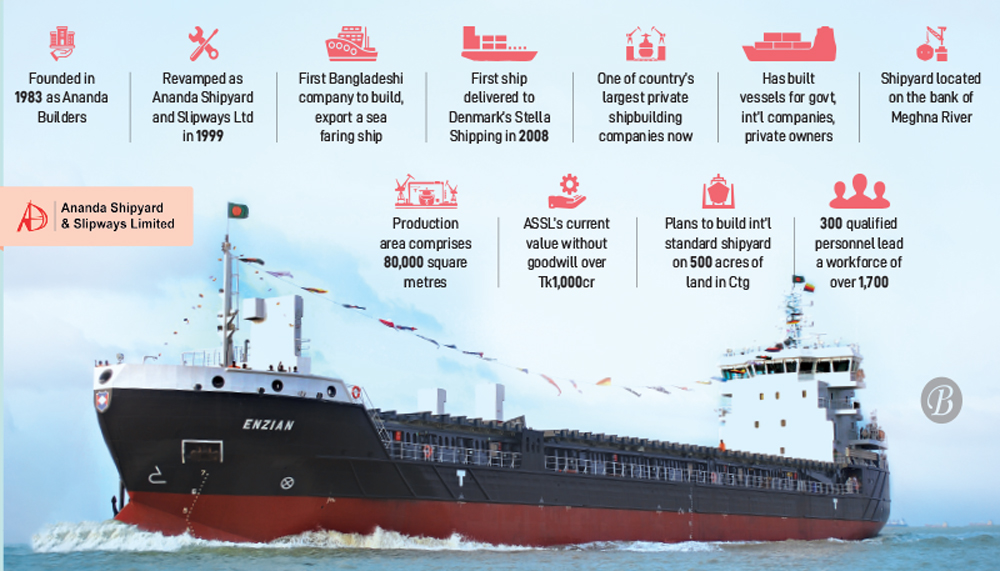

As the business grew, in 1985, the shipyard was shifted to its present location on the bank of the Meghna River. In 1999, the company revamped itself, modernised and increased its capacity, and rechristened Ananda Shipyard and Slipways Ltd (ASSL).

In 2008, the company built the first ever seagoing ship and exported it, announcing Bangladesh’s entry into the global shipbuilding industry and opening new horizons for this sector here.

At present, ASSL is one of the largest private shipbuilding companies in the country. The production area of ASSL comprises 80,000 square metres. Shipbuilding halls are fitted with EOTS and slipways are with gantry cranes. The yard’s workshop is also fitted with modern machinery and equipment.

Some 300 qualified and experienced personnel are leading a workforce of more than 1,700 people in the sections of lofting, cutting, welding, erection, fitting, woodworking, mechanical works, electrical works, painting and quality control, painting and producing reasonably modern quality vessels. The in-house computer-aided design office provides designs and drawings to the shipyard.

The Business Post recently sat down with ASSL Chairman Bari and Managing Director Afruja, where they shared their dreams, humble beginnings and struggles.

Bari said his technical knowledge and Afruja’s administrative skills made the company what it is today. “Yes, we were the first to privately build class vessels in Bangladesh and export them. We did it successfully. But it was not so easy.”

“We have built and exported more than 10 class vessels. We have built over 350 cargo, bulkhead, container and other types of vessels. We have also worked on various big projects including making pontoons for many ghats and repaired many big ships, including rescue vessel Rustom and its 60-tonne salvage crane,” he said.

ASSL has completed 27 marine crafts under special surveys of Lloyd’s Register, Nippon Kaiji Kyokai and Germanischer Lloyd. The company’s value without goodwill currently is over Tk 1,000 crore, according to Bari.

In the beginning…

Bari was a young man when he joined the fight for independence during the 1971 Liberation War. He met Afruja by chance when freedom fighters took shelter in her family’s house one day. The two became close very soon and they got married in the middle of the war.

After independence, Bari got enrolled on the first batch of the Department of Naval Architecture and Marine Engineering at the Bangladesh University of Engineering and Technology (BUET). Four years later, after graduating, he joined Bangladesh Inland Water Transport Authority (BIWTA).

In 1979, Bari went to England to do his PhD with a Commonwealth scholarship. While he pursued that, Afruja, who also went with him, completed a diploma and started working to earn money.

Bari re-joined BIWTA in 1982 when the couple returned home after he was finished with his PhD in shipbuilding and shipping from Newcastle University. Later, he also worked in Bangladesh Inland Water Transport Corporation. In 1985, Bari joined BUET as a teacher.

However, both of them were always thinking about doing something for the shipping industry. Passionate about waterway vessels because of his studies and work, Bari used to discuss the construction, design and various issues of vessels and ships with his wife.

Bari said they could see the potential of the shipbuilding industry in Bangladesh while studying and interacting with people from this sector abroad. “Bangladesh is a riverine country and has cheap labour. So, it was relatively easy to establish a shipbuilding industry here.”

In 1983, Afruja with the help of her brother founded Ananda Builders and set up the company after renting land in Keraniganj with the money she had saved up in England. Bari left BUET and joined the business in 1987.

“Afterwards, we started expanding the business together,” Bari said.

The couple named the company after their first child Ananda, a son who died at the age of 5 in 1978. They now have three daughters, all of whom are highly educated and work with their parents.

The experiences

In the beginning, the company did some small work. In 1985, they managed to buy 27 bighas of land near Meghna Ghat and the full-fledged journey started in 1987.

In 1988, the shipbuilding division of Ananda Builders made 8-10 aluminium boats for Dhaka WASA to carry fresh water to flooded areas.

“One of the significant works for us was making a crane vessel for BIWTA in 1992 under a project financed by the World Bank. That project was worth around Tk 1.48 crore,” Bari reminisced while talking to The Business Post.

“Another big project was repairing the 60-tonne crane of Rustom in 1994. I am proud of doing this successfully because we did it without a real engineering facility at the time,” he said.

Claiming no one else in Bangladesh could have done that job, Bari said, “It was very challenging. We repaired it using proper engineering methods and Rustom is still running.”

In 1995, BIWTA floated an international tender for two 1,000-horsepower tug boats and 100 pontoons. It was a Tk 100-crore project financed by World Bank as well, he said.

Ananda Builders beat 11 companies and bagged it with the lowest offer. However, the authorities did not want to give them the work at first due to some problems, he said. “We managed to get the work two years later after solving all issues.”

“It was a two-year-long project but we completed it in 14 months. Since there were 10 months and some more money left, BIWTA asked us to build 50 more pontoons. We finished that Tk 50 crore project on time too,” Bari added.

Beginning of ship export

Around the 1990s, Bari said, their company used to get projects to make pontoons and ferries through the government, based on funding from aid organisations related to the government of Denmark, as authorities started to take notice of the quality of their work.

“At the time, we were importing shipbuilding materials amid some VAT and tax-related problems. In 1998, I met with Shah AMS Kibria, the then finance minister, and urged him to allow bonded warehouse facilities for international tenders. The facility was given after authorities found it feasible,” he said.

By 1999, when the company was rechristened ASSL, two paved slipways were built at the dockyard in Meghna Ghat for building large ships. Bari said those were the first of their kind built in Bangladesh after the British.

The same year, foreign consultants surveyed the shipyard’s facilities and work quality. They were followed by a technical team to evaluate their capacity to build export-quality ships. “Until 2004, that team pointed out many problems at the shipyard and helped us properly fix them to achieve and maintain the international standard,” he said.

ASSL received the first direct order to export a ship from Denmark’s Stella Shipping in 2005. The vessel, named Stella Maris, weighed 2,900 tonnes and cost around $5.5 million to build, Bari reminisced.

“But we encountered another problem in 2006. The buyer demanded a bank guarantee to make the first payment. But no bank here was able to provide that facility at the time. After many efforts, a bank gave the guarantee with special permission from the Bangladesh Bank,” he said.

Later, ASSL built the ship successfully and delivered it on May 15, 2008. This was the first time that any Bangladeshi company exported a ship, Bari said.

“Stella Shipping was very happy with the vessel’s quality and ordered another similar ship. That was the beginning of our export-oriented work and we have never looked back,” he said with pride.

In September of that year, ASSL attended the Shipbuilding, Machinery and Marine Technology trade fair in Germany representing Bangladesh as a shipbuilding nation.

“After we returned from there, we received orders from various countries, including Denmark, Germany, Sweden and the Netherlands, to export 24 ships. Those were about $324 million worth of works,” he added.

Tackling the troubles

Talking to The Business Post, Afruja Bari said they faced the most problematic times after receiving the new orders.

“We started building the first 10 ships in 2009. We needed money to build them but no bank could finance us. Meanwhile, the buyers wanted bank guarantees to send money in phases because the ships were being built in Bangladesh. And if we can’t deliver them, we were liable to refund them,” she said.

“After many attempts, we managed to convince a bank but it was able to fund eight ships. Soon after, as we knew its managing director at the time, another bank graciously agreed to finance us for the other two ships.

“Half of the ships were nearly ready when the two banks could not maintain the guarantees. At the same time, the global recession took hold and many buyers cancelled orders. We borrowed money from different parties and imported materials to build the ships. We had to pay them. We were also bound to return the full amount with interest to the buyers. It was such a troubling time,” she said.

“We were in serious trouble because of the incapability of our country’s banks but they were not liable for this,” Afruja lamented.

“Some vested quarters also started spreading propaganda against us. It took around three years of struggle to manage the money, handle all the problems and get a clean chit from everyone, including the authorities concerned here,” she said.

“By then, six ships were ready to be exported but only three of them were delivered. The four other ships were still under construction,” she added.

Addressing the funding-related problem, both Bari and Afruja said, “In our country, banks want properties or other guarantee agents as a mortgage. Who has such assets worth Tk 200-300 crore for that? That’s why the banks here don’t want to finance shipbuilding. This is the biggest obstacle hindering the industry’s growth.”

“But if we look at what’s happening abroad, we see that banks are financing shipbuilding against ship mortgage. If banks here start doing this, there is scope to make this industry much better than it is now,” they stressed.

Future plans

Since its inception, ASSL has undertaken many projects secured through international tenders for the government and funded by the government and donors, as well as for private owners.

Some German investors had also shown interest in financing them to build an international standard shipyard after ASSL received an order to build 24 ships in 2008, Bari said.

“Based on that, we have been working on this and have the whole shipyard structure’s design ready. We need 500 acres of land in Chittagong to build this shipyard with a dry dock, where vessels will be built and repaired.

“We can proceed only if the government allocates the land. This is $2 billion worth of work. If it’s done, it will be a milestone for Bangladesh and the shipyard will be the 4th largest in the world,” he said.

“Meanwhile, we have prepared our second generation to flourish in the shipbuilding industry. Our family members will handle the projects after we retire,” he added.

Afruja and Bari said the industry has much potential because Bangladesh has suitable weather for shipbuilding and hardworking labourers, who cost lower than in other countries.

They said the government made a policy to develop the shipbuilding industry two years ago. Amid the Covid-19 pandemic, the government had also allocated Tk 5,000 crore for this industry’s recovery and development.

“Only Tk 2,000 crore has been disbursed but the industry people are yet to get that because the money is still stuck at banks due to bureaucratic complications. We have not seen much progress,” they said.

“Demands for ships and such vessels will only rise in future. Bangladesh will be able to capture a large portion of the global market if the government provides the necessary support,” said the couple.