Home ›› 18 Sep 2021 ›› Corporate

The annual demand for aluminium extrusion products in Bangladesh is estimated to be around 60,000 tonnes. Ten local companies, including PHP, are meeting 90 per cent of the demand. In an interview with The Business Post, PHP Family’s Executive Director Mustafa Jamal Hossain identified maintaining product quality, absence of guidelines and uneven competition as significant challenges for the aluminium sector.

The Business Post: What’s driving the increasing demand for aluminium extrusion products?

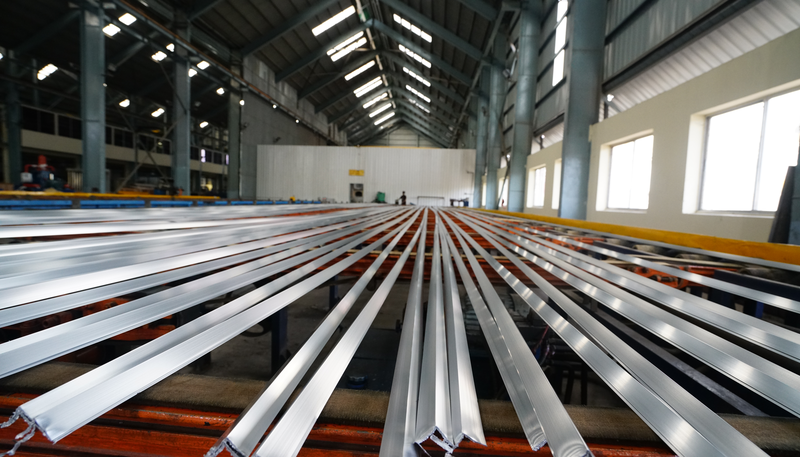

Mustafa Jamal Hossain: The demand for aluminium extrusion products has been gradually rising due to their attractive appearance, lightweight, strength, corrosion resistance, durability, ease in construction and maintenance. They are popular materials for use in modern buildings.

Besides, our infrastructure is improving rapidly. People’s mindsets and tastes in architecture are also evolving. Though we have an impressive GDP growth rate, we are yet to get a good score in ease of doing business.

PHP is growing faster, thanks to our dedication and the business policy of PHP Family’s founder Chairman Sufi Mohamed Mizanur Rahman.

TBP: What kind of challenges are the industry people facing?

Mustafa: The applications of aluminium range from door frame, sliding frame, office decoration, fitting and angle, automobile sector, heat sink, textile frame, furniture, to aeronautical engineering and so on.

Maintaining product quality, absence of guidelines and uneven competition are major challenges in the sector.

Some aluminium factories are supplying low-quality products at low prices by taking advantage of zero guidelines. Bangladesh Standards and Testing Institution and other government authorities concerned should set a minimum standard for the sake of the sector.

TBP: What kind of policy support does the sector need to grow further?

Mustafa: Aluminium extrusion profiles should be approved as one of the building materials in the building code. We want the same facilities as other sectors of building materials. For example, rod and cement sectors pay 3 per cent source taxes but we have to pay 5 per cent.

Why do we have to pay 5 per cent Advance Income Tax? We urge the government to fix it to 3 per cent to help the sector flourish.

TBP: There are a good number of aluminium manufacturing companies. Why will people go for PHP products?

Mustafa: PHP is one of the largest conglomerates in the country. Some 10 companies are currently manufacturing aluminium extrusion products here. The sector has been growing rapidly since 2000. PHP products have been winning customers’ hearts since 2010 as we have both aluminium and glass items.

PHP offers brand quality, loyalty as well as commitment. The company maintains genuine guidelines as per the building code.

The profiles have thickness and hardness as per the approval of BSTI. Besides, PHP uses imported billet instead of low-quality raw materials.

We are also producing new products, such as PHP Shiny, an updated version of aluminium extrusion products. So, more people are buying PHP products.

TBP: What is your company’s annual growth rate?

Mustafa: Our growth rate is 10 to 15 per cent per annum. We sold 949 tonnes of PHP profiles in 2016 that increased to 2,028 tonnes in 2020. We hope the figure will go up to 3,500-4,000 tonnes this year.

We have set up new machines in our factories in August this year to produce more quality products. Our current yearly production capacity is around 7,800 tonnes.

We also sell 50,000-60,000 tonnes of PHP glasses each year.

TBP: Do you have any plans to export goods?

Mustafa: No, we do not right now. The market size of Bangladesh is around 5,000 tonnes per month. We want to grab our local market first as it has vast potential.

TBP: How do you plan to grab more market shares?

Mustafa: For now, we are planning to bring new and quality profiles. We want to update our products with global profiles, innovative designs, and research for modern technology that would enable us to produce stronger and lighter profiles to reduce building weight.