In the conventional method, it takes three to eight days to get dried fish from fresh fish. It also depends on good weather. If the weather is good and there is enough sunshine, fish can be dried quickly.

If fish is dried in the sun for a long time, it can attract various types of insects and flies. So, producers often use different types of pesticides to protect dried fish from insects or flies, which is very harmful and unsafe for the human body.

Another major problem with the conventional method is that fish may rot in the middle due to a lack of heat from the sun.

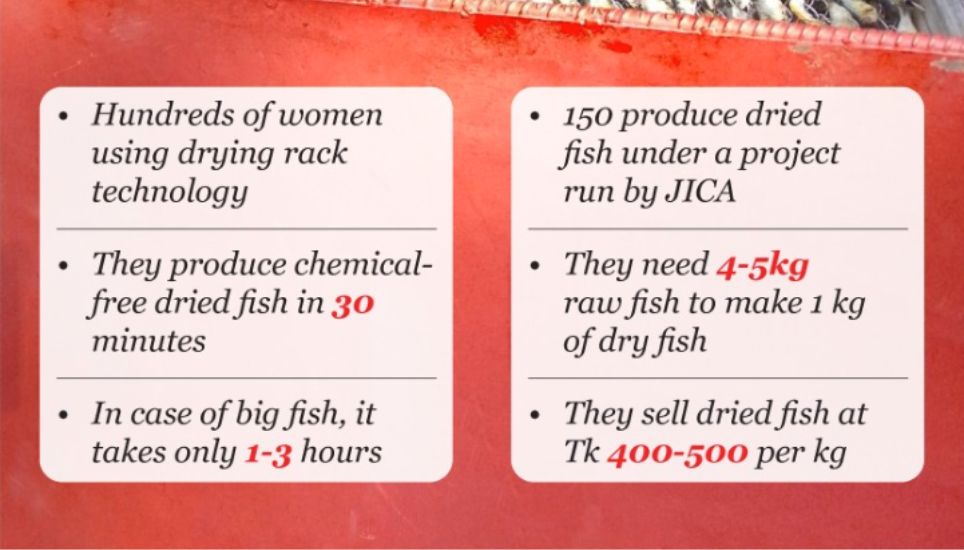

However, avoiding all these, hundreds of women in Cox's Bazar are making dried fish from small fresh fish within just 30 minutes. There is no need to use any kind of chemical or pesticide in the process. They can make dried fish within a very short time, using the tray-oven drying rack technology. So, this dried fish is safe and healthy.

Visiting various areas in Cox’s Bazar, it was seen that women buy fresh fish from local fishermen and produce dried fish with the help of technology.

Some of these dried fish are sold to local tourists and the rest of dried fish are taken to the local market. The producers said that the demand for their dried fish is also increasing day by day as they do not use any kinds of chemicals.

Officials of a Japan-Bangladesh financial cooperation project titled Fisheries Livelihood Enhancement Project (PHILEP) are supporting them in these works. A total of 150 men and women, divided into 23 groups, are producing dried fish under the project run by JICA.

Rabeya Begum, president of one of the groups, hails from North Sonar Para village in Jhowban area of Ukhia. She said, "Earlier, we used to dry it in the sun on the sea beach. In case of small fish, we had to dry it for at least three days. However, for big fish, it took up to eight days."

“If sunlight is low, fish would rot. But using this tray-oven drying method, we can dry small fish in 30 minutes. And in case of big fish, it can be dried in 1-3 hours, depending on the species and size.”

She also said if the weather is good and the heat of the sun is high, the cost can be reduced. “That's why we dry half of it in the oven and dry it in the sun on a drying rack inside a mosquito net.”

On the one hand, there is no possibility of fish rotting and on the other hand, the cost of gas is saved, she added.

Fatema Begum, president of another group, said they need 4-5 kg of raw fish to make one kg of dry fish. “We can buy small fish at Tk 70-80 per kg and make dried fish and sell it at Tk 400-500 per kg. In last 15-20 days, I sold about Tk 5,000 worth of dry fish.”

She said, "I have been producing dry fish for eight years. Using this technology seems very timely to me. So, I have been using this technique for over a month,” she added.

Although the drying rack has the capacity to produce up to 150-200 kg of dried fish per day due to less fish catch from the sea and capital shortage, they are able to produce 5-6 kg of dry fish per day. If the supply of raw fish increases, the amount of dry fish will also increase, according to members of various groups.

How to dry fish

A gas stove is placed under a steel oven, 2.5 feet by 3.3 feet, with an open top. Above that hearth hangs an iron plate on the first level where the heat of the fire comes directly. On the second level, there is a tray where the heat of the iron plate and the hot air come in.

If the fire is lit and the fish is spread on the tray, the fish starts to dry slowly at the specified and controlled temperature.

At first, various sea fish like laitta, knife, prawn, lakshma, karati, surma, madhu faisya, rupchada, poa, and coral etc are cut and cleaned. Then these are washed in fresh water and kept in a sieve or hung for a while to drain. When water comes out, it is placed in a tray-oven to dry.

Project consultant and expert Md Shafiuddin said after removing water from raw fish by blowing hot air of LPG stove controlled heat in the tray-oven, dry fish that is being made can be converted into fresh fish again and cooked by soak in water again. So, the nutritional quality of these dry fish is also good, he added.

Women benefit from drying rack tech

While talking about this technology, the officials concerned said that it needs a set of tray-oven, a set of drying rack, two baskets and two drums for cleaning fish. The total cost of the package is Tk 60-70 thousand that is provided free of cost for every group of 11 people in the primary stage. Apart from this, training is also being given in using them.

Shafiuddin said that this technology and design are all made in Japan. This is the first in Bangladesh. Advantage of this method is that dry fish can be made even during rainy days. Earlier, they used to get worried if fish in the catch remained unsold. Now they keep it dry for a short time, and then sell it at a convenient time.

Traditional method

In the traditional method, producers use salt to gain extra weight of dried fish. Besides, drying in open environment leads to fly and insect infestation. They also dry fish in an unhygienic environment.

According to various sources, they use powdered pesticide called DDT which is harmful to human health. Due to its use, dried fish do not rot easily and insects or bacteria cannot attack dry fish.